About the Electron beam lithography facility

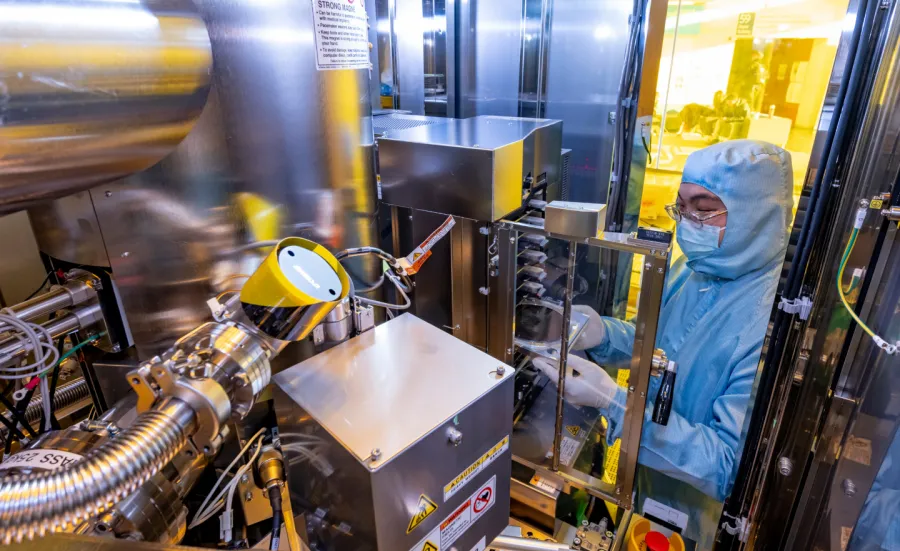

网络彩票APP下载_澳客彩票网-官方游戏, Electron Beam Lithography (EBL) facility hosts the first 200 kilovolt (kV) system outside of Japan - the JEOL JBX-8100 G3. The high acceleration voltage allows ultra-high resolution processing of fine structures to sub-5 nanometres (nm). This can be achieved in thick resist - up to 10 micrometres (μm) - with almost vertical sidewalls.

Using the higher kV setting, we can also extend its use beyond lithography to electron displacement.

The system creates new opportunities for fine-geometry capability in novel device fabrication, across electronics, photonics, and bio-nano technology. It is available for collaborative research.

The facility is supported by a grant from the Engineering and Physical Sciences Research Council (EPSRC).

Read the grant page on the EPSRC website

Read the news piece on the JBX-8100 G3

The wider EBL facility

We have developed lithography processes for a number resist types, detailed in the technical specification.

We use Genisys software to carry out pattern optimisation. This enhances the high resolution and throughput of the electron beam. Using patterns created from CAD files, we can make rapid design changes without photomasks.

We have dedicated spin coaters and hotplates for electron beam resist coating processes.

网络彩票APP下载_澳客彩票网-官方游戏, EBL tools are integrated with the latest ultra-high-resolution scanning electron microscope (SEM), the JEOL IT-800i. This is optimised for semiconductor materials and fabrication characterisation purposes. The facility can also provide “mix and match” lithography, in conjunction with the deep-ultraviolet scanner.

In late 2024, the facility will receive a second EBL tool, the JEOL JBX-A9, a high-volume 300 mm wafer, 100kV tool. This will also be the first of its type outside of Japan.