About the Silica fibre facility

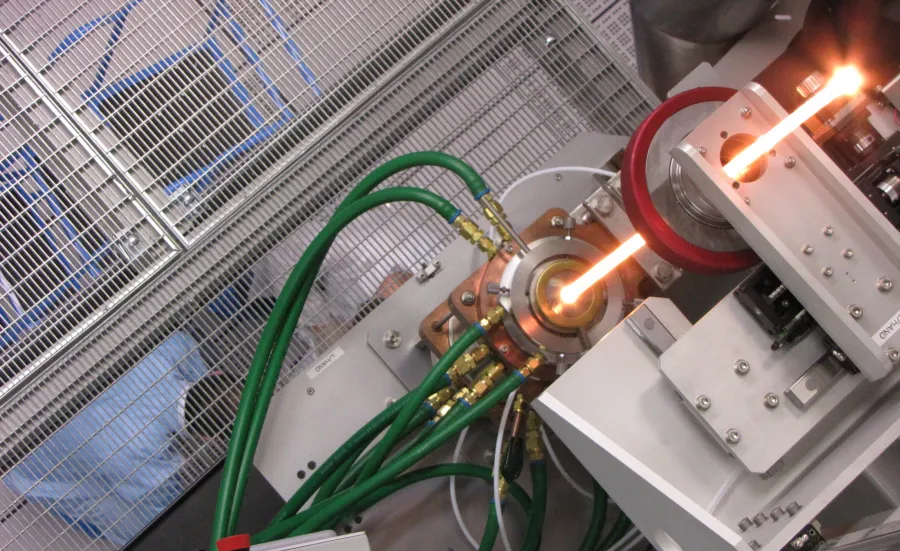

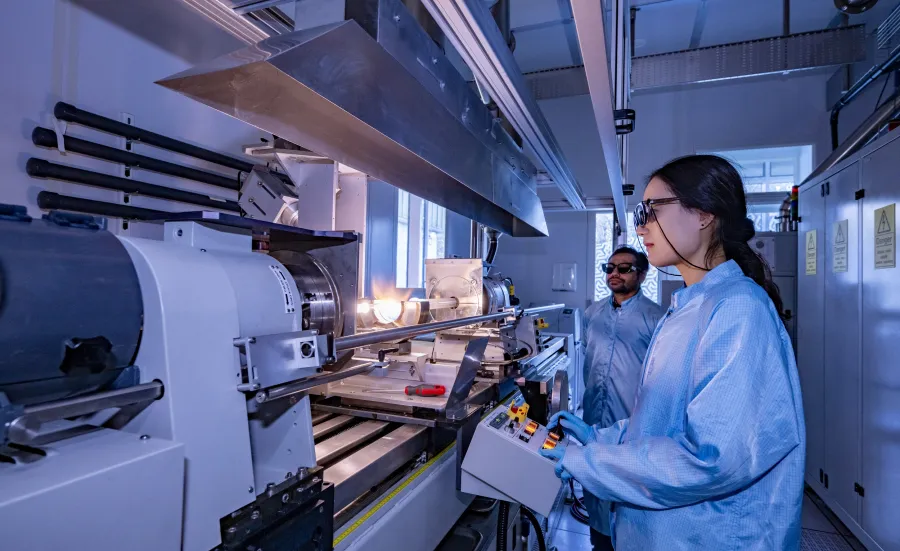

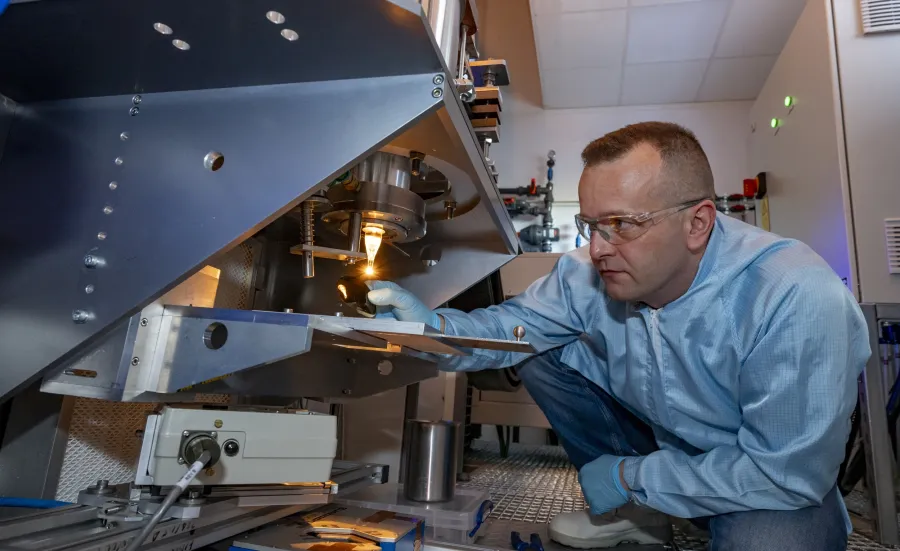

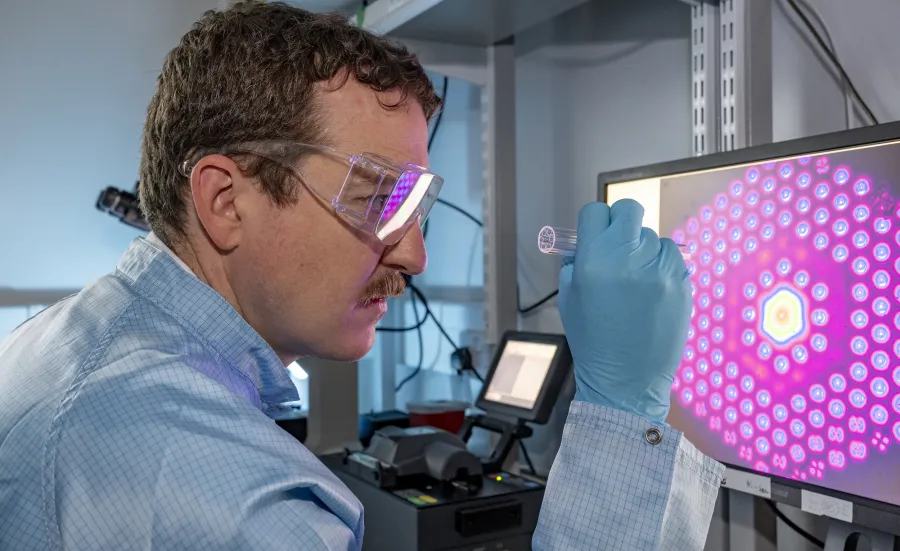

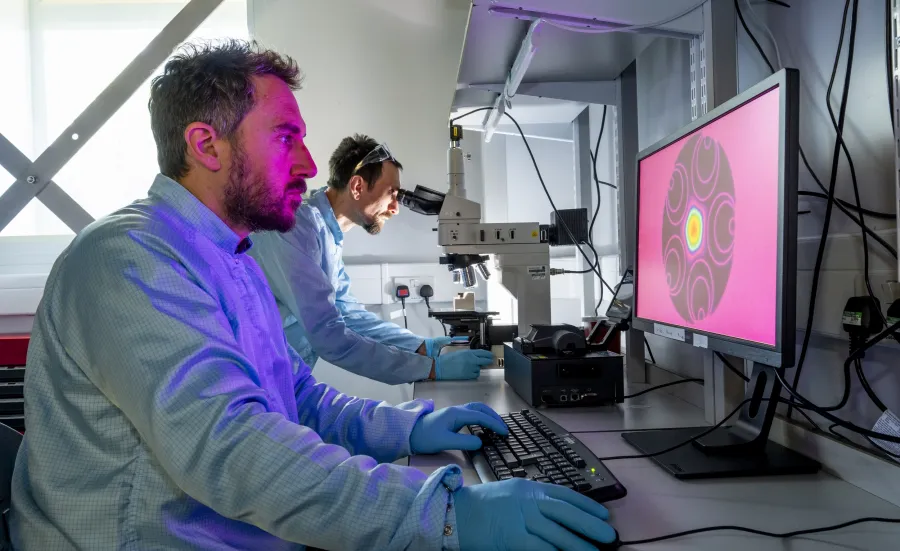

We specialise in the manufacture and research of doped and structured fibres. 网络彩票APP下载_澳客彩票网-官方游戏, equipment includes fibre towers and modified chemical vapor deposition (MCVD) lathes. We also house a range of preform and fibre characterisation tools.

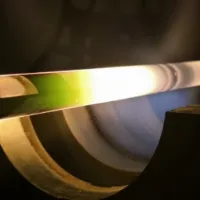

We produce industry-standard passive and active preforms and fibres. We also manufacture specialist fibres with complex structures, for example hollow core fibres. This enables research into high-power fibre lasers and advanced telecommunications and sensing devices.

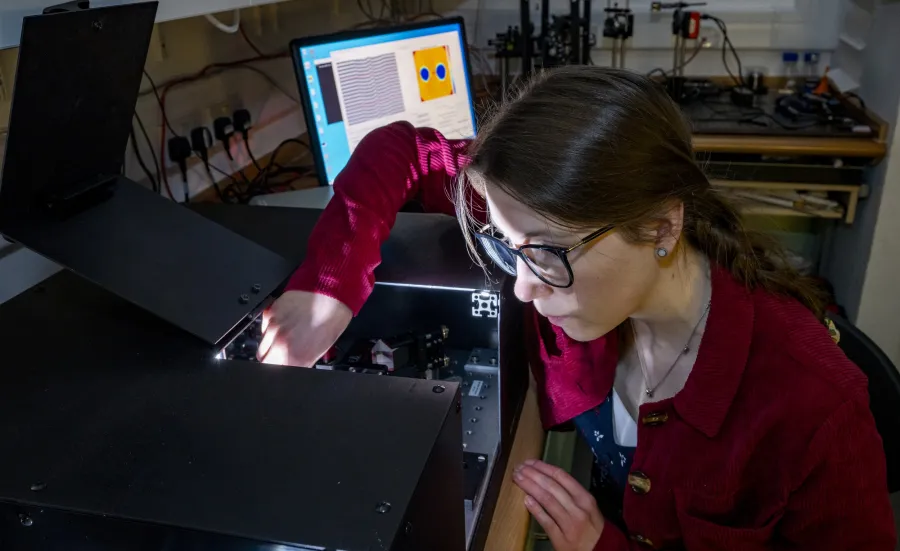

?Complete post-processing and characterisation of silica fibre includes:

- preform and fibre index profilers

- fibre proof-testing

- high-resolution optical time domain reflectometry (OTDR)

Highlights

- we produce a range of fibre types including ribbon, spun, bundle and microstructured. We also produce fibres with dimensions in the 50 to 1500 micrometre (μm) range

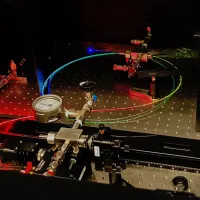

- features of our drawing tower include both conventional thermal and ultra-violet (UV) cured polymers, as well as novel high temperature UV cured polymers and novel dynamic preform spinning

- we use well-established outside vapor deposition (OVD) technology to explore high-volume fabrication of rare-earth doped glasses

- we use MCVD in-situ solution doping and vapour phase techniques. This allows us to create next generation rare-earth doped fibres for high power lasers

- low loss hollow core fibre fabrication. Against conventional technology, we see lower losses at telecommunications wavelengths. We achieve similar in the UV, visible and mid-infrared

- 10 kilometre continuous draw of low-loss, uniform lengths of hollow core fibre?